Problem:

Applying Lubricants To The Center bowl Does Not Work

High bearing pressure extrudes both lubricants and normal non-metallic liners from the centerbowl, leaving metal-on-metal contact. The result is poor curving performance and accelerated wheel and track wear. In extreme cases, track rollover and car derailment can occur.

Solution:

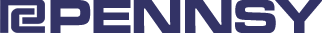

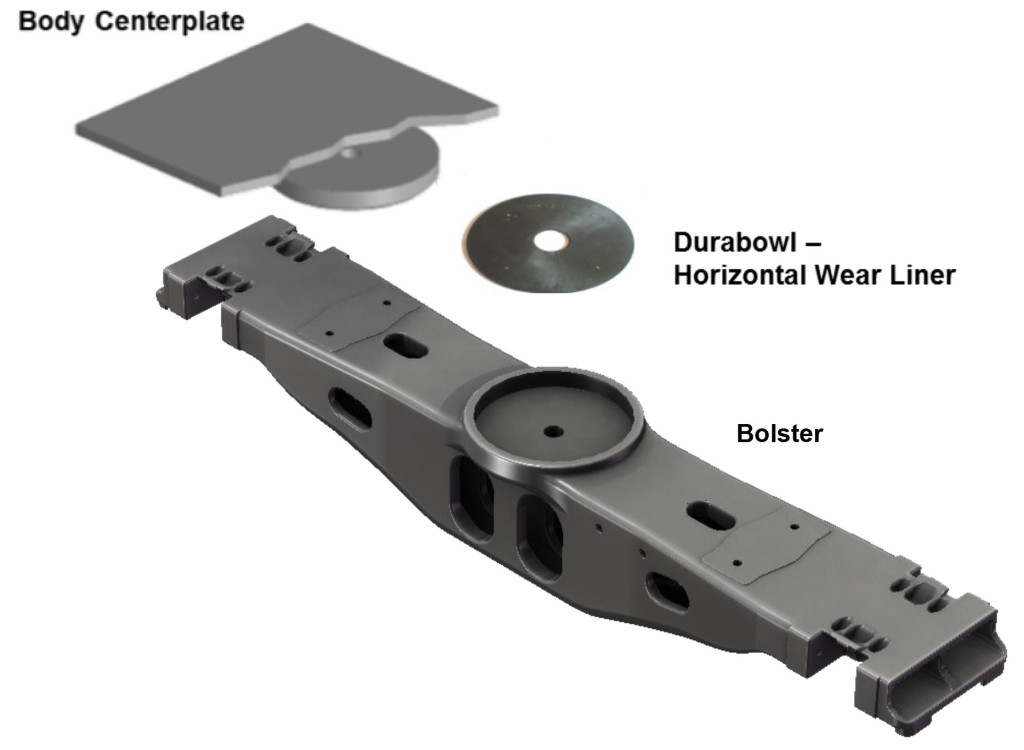

Pennsy Durabowl Horizontal Liners

The Durabowl’s rugged high grade polymer was chosen for its low coefficient of friction, excellent cold flow resistance and ability to withstand high impact loads. It’s easy installation eliminates the time-consuming process of welding dissimilar metals. Extensive lab and field testing has proven the Durabowl outperforms and outlasts all other centerplate wear protection products available on the market today.

Results:

- Low Turning Resistance Improves Curve Negotiation; Coefficient of Friction 0.27

- Cold Flow Resistance Withstands High Bearing Pressure and Eliminates Extrusion

- Easy Drop-in Installation

- Eliminates Metal-on-Metal Contact, Drastically Reducing Costly Repairs

- Lab and Field Testing Have Proven Longevity and Performance

Durabowl Applications

| Durabowl Horizontal Wear Liner Size | Durabowl Horizontal Wear Liner Part No. |

|---|---|

| 16″ STD x 1/4″ thick | PN2529 |

| 16″ STD x 1/8″ thick | PN2678 |

| 14″ STD x 1/4″ thick | PN2531 |

| 14″ STD x 1/8″ thick | PN2680 |