Problem:

Unintended Hose Separations

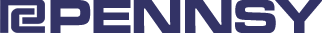

Unintended air hose separations cause costly train delays. The use of larger 2″ rings in the trainline trolley allows the air hose assembly to hang lower, increasing the potential for hose separations. Additionally, current metal rings wear against the trolley rod. When wear or damage occurs, the ring assembly arrangement is time-consuming to repair, and requires extensive welding and destruction of parts for even minor repairs.

Solution:

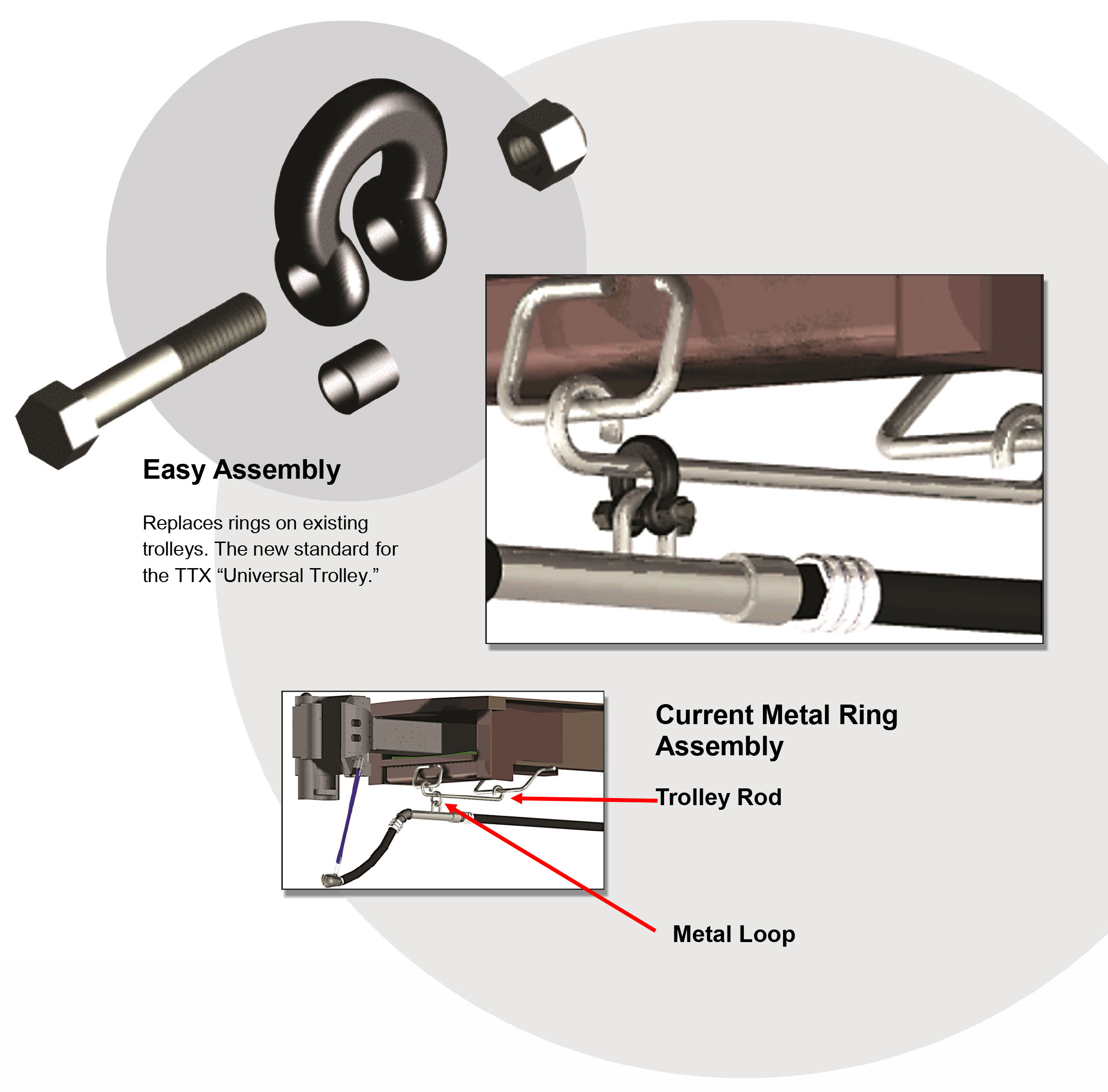

Pennsy's Retrofit Loop

Pennsy’s Trainline Trolley features a long wearing polymer coating that eliminates all metal to metal contact, protecting the trolley rod, pipe and nipple assembly from wear. Pennsy’s shackle also eliminates all welding and allows for easy air hose change outs and other repairs – all of which can be performed in the field. Pennsy’s polymer has a low coefficient of friction, allowing for smoother movement during buff and draft, greatly reducing the likelihood of binding that can cause costly air hose separations.

AAR Testing:

Extensive Lab Testing

Pennsy’s Retrofit Loop exceeds the AAR 3000lb pull test requirement. During lab testing the current metal ring design needed to be replaced at 60,000 full travel cycles (16″ travel). Pennsy’s polymer lined retrofit loop showed only minimal wear at 150,000 cycles.

Results:

- Reduced Trolley Maintenance – Polymer Liner Eliminates Rod and Ring Wear

- Exceeds 3000# AAR Pull Test

- Lower Coefficient of Friction Means Smoother Movement During Buff and Draft and Helps Alleviate Unintended Air Hose Separations

- Loop Maintains Proper Alignment During Buff and Draft Movements

Pennsy's Retrofit Loop Design