Problem:

Low-Grade Air Brake Hose Supports Cannot Handle Severe Railroad Demands Leading to Replacements, Adjustment Costs and Train Delays

Not all air brake hose supports are created equal, a statement made evident in railroad revenue service where inadequate supports frequently fray, tear, and fail. Each year adjustments, replacement costs and train delays cost the industry more than $15 million per year. Typical failures are due to environmental degradation and from peak loading typically associated with uncoupled hose flailing.

The more stringent AAR S-4006.2008 specification has necessitated a new generation of supports and attachment mechanisms specifically designed with higher performance in mind. This improved performance must come without sacrificing ease of installation and adjustment.

Solution:

Pennsy’s Resilient Airbrake Hose Support

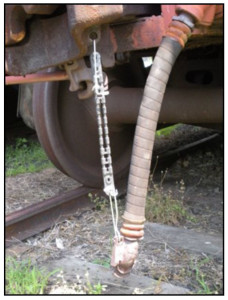

Pennsy’s Resilient Polymer Air Brake Hose Support With EZ-Adjust Railroad-Grade Clips Increases Performance and Decreases AAR Billing Costs and Train Delays.

Pennsy’s new Resilient air hose support was designed specifically to exceed the demands of the AAR’s revised testing specifications. The body of this unique polymer support provides resilience never seen before in an air hose support. It will return to its original shape even after stretching 8+ inches and lifting 360 pounds and will maintain this excellent elasticity down to approximately -40C! It also eliminates the hazard of frayed cables and greatly outperforms environmentally unstable rubber strap materials. The strongest attachment clips in the industry make it simple to install and adjust as needed. The result is a more durable support that will last longer and not require height adjustments.t

Results:

- Exceeds AAR S4006-2008 testing requirements.

- Resilient polymer stretches, cushioning hose flaying.

- Durable polymer returns to original shape after stretching, virtually eliminates hose height adjustments.

- Maintains elasticity down to -40C.

- Railroad-Grade attachment clips – strongest in the industry

- Fewer hose separations and train delays yields potential net velocity increases

- Decreased hose support maintenance and replacement costs

Railroad-Tough Support Fewer Air Hose Separations

Tested Tough

- Exceeds all AAR S-4006-2008 Requirements

- Max Load Test; 360lbs, 8.4″ stretch, with less than 0.25″ permanent set

- Permanent Set; 0.5″ Elongation, 0″ permanent set

- Ozone testing; ASTM D1149 @ 20% elongation; Pass, No cracking

- Able to stretch 10+” and lift 500+lbs without breaking

Railroad-Grade Heavy Duty Clips

- Patented clip design provides extreme durability

- Patented clip design allows for maximum loading

- Strongest clip available in the industry

- Gladhand R-Clip resists rotation and lateral loading – a common cause for clip failure.

- Easily installed and adjusted with a gloved hand

Durable, Flexible Polymer

- Flexible – Provides cushion to flaying hoses.

- Durable – Close to zero permanent set virtually eliminates costs for hose height adjustments

- Longer Lasting than rubber and cable Supports – Reduces AAR Job Code 1165 expenses

- Impervious to environmental and temperature extremes; maintains elasticity down to ~-40C.

- Overcomes safety hazards associated with frayed cable supports