Problem:

If a bottom rod connection fails there is potential for a train derailment.

In the past, derailments from failed bottom rod connections have resulted in the Association of American Railroads’ mandating bottom rod safety supports per AAR Interchange Rule 10.

Failures can occur from an improperly applied, broken, or worn out cotter pin.

Solution:

Pennsy's Bottom Rod Safety Support

Truck bottom rod safety supports are required on trucks that have brake rods which pass underneath the truck bolster.

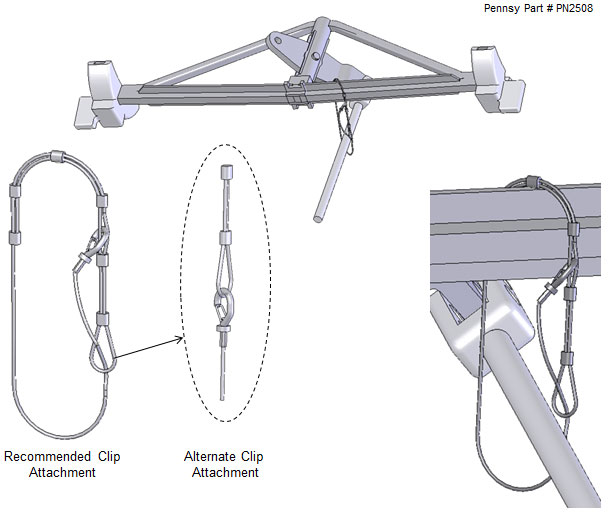

The Pennsy Bottom Rod Safety Support is manufactured from galvanized steel braided cord with a galvanized hook that allows for quick and easy application.

This support can hold a static load greater than 1200 pounds, well in excess of AAR requirements, and easily survived the 200 pound 1,000 cycle drop test.

Results:

- Easy application and removal in all weather conditions

- Exceeds AAR Specification S-399-92

- High strength braided cable that can hold in excess of 1200 pounds.

- Exceeds the 200 pound 1,000 cycle drop test

- Six segments allow for multiple length adjustments

- Lab and field testing have proven longevity and performance

Pennsy Bottom Rod Support Application Instructions

Application Instructions

- Follow all applicable safety rules.

- Wrap Pennsy Bottom Rod Support PN2508/PN2754 over brake beam and under brake bottom rod.

- Engage bottom rod support clip into one of the six adjustment positions to obtain the least amount of slack.

Note: It is recommended to feed the clip thru the end loop whenever length allows and on all shorter adjustments