Problem:

Safely and Efficiently loading and unloading Automobiles in Autorack Freightcars

- Bridge Plates are used to cross the gaps between autorack freightcars, and therefore must be strong, each plate being able to hold a 10,400 pound static load.

- The Bridge Plates must be portable enough to allow crews to carry up and install at the top decks of autoracks. The Autorack bridge plate must weigh 40 pounds or less.

- The riding surface of the Bridge Plate must have a durable anti-slip coating present. Worn or degraded anti-slip surfaces present a safety hazard.

- Current hinge designs degrade due to the demanding operating environment and are continually replaced.

Solution:

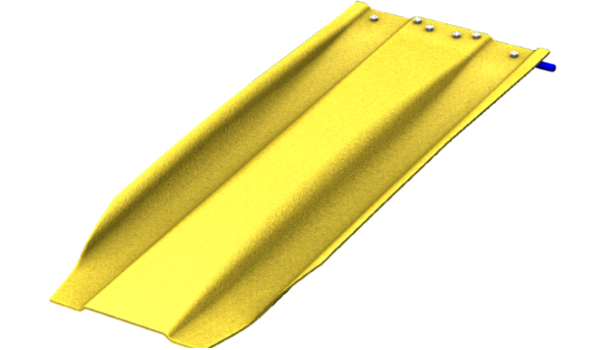

Pennsy’s High Capacity Bridge Plate

- Pennsy’s High Capacity Bridge Plate is made from aerospace grade aluminum, one of the strongest in the market.

- Pennsy’s bridge plate undergoes very little distortion when a load is applied to it. Competitor bridge plates distort greatly.

- Our aluminum is primed with an advanced E-coat primer, then a high-visibility anti-skid epoxy is applied to the running surface, which provides superior adhesion to the non-skid coating.

- Pennsy’s High Capacity Bridge Plate features an improved hinge design that will provide a longer service life, and smoother operation.

AAR Testing:

Tested to AAR specification M-951

Pennsy’s High Capacity Autorack Bridge Plate has been extensively tested to ensure safe operation. The Pennsy Bridge plate exceeded both the static load as well as the dynamic load requirements of AAR M-951.

Results:

- High-visibility and durable anti-skid coating

- Exceeds M-951 Static and Dynamic load requirements

- Improved hinge durability

- Improved non skid coating adhesion

- 56” and 53” Lengths Available

- Less than 40lbs