Problem:

Wear on the pedestal roof can lead to premature degradation of the side frame. Current wear liners have a short product life.

Metal on metal contact can lead to premature degradation of the pedestal roof. Current wear liners crack and break easily. The FRA mandates that cracked and broken wear liners must be replaced.

Solution:

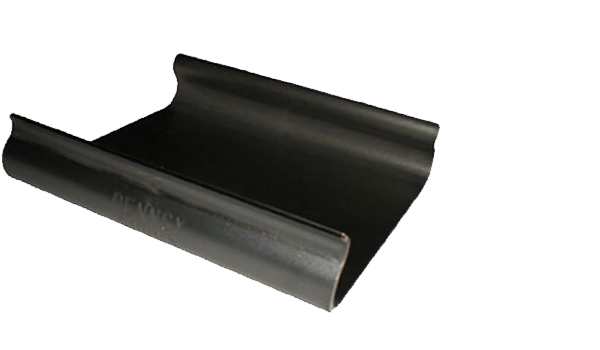

Pennsy's Pedestal Roof Liner

Pennsy has designed a Pedestal Roof Liner that has higher elongation and is less brittle than competitive liners currently available.

By studying failure modes in the field and continuing our research using FEA analysis, Pennsy has selected a material with properties ideal for a pedestal roof liner.

Superior material selection has enabled our liner to outperform and outlast all other competitive pedestal roof liners. Laboratory fatigue testing in the vertical and lateral direction have confirmed our claims.

Pennsy’s Pedestal Roof Liner can be used on new or reconditioned side frames.

Results:

- Laboratory tested with 10x better performance in the vertical and lateral fatigue testing

- High elongation – three times higher than our competition

- Less brittle and more malleable

- Excellent wear resistance

- Easy and safe pop-in installation

- Eliminated pedestal roof wear, drastically reducing costly repairs

- 300 lbs. pull-off test, will not disengage during side frame transit

Material Properties

| Competitor* | Pennsy PN2545 | ||||

|---|---|---|---|---|---|

| Metric | English | Metric | English | ||

| Hardness, Rockwell B | 95 | 95 | 70 | 70 | |

| Tensile Strength, Ultimate | 724 MPa | 105000 psi | 450 MPa | 65300 psi | |

| Tensile Strength, Yield | 400 MPa | 58000 psi | 345 MPA | 50000 psi | |

| Elongation at Break | 12% | 12% | 33% | 33% | |

| Modulus of Elasticity | 200 GPa | 29000 ksi | 200 GPa | 29000 psi | |

| Poisson’s Ratio | 0.29 | 0.29 | 0.27 | 0.27 | |

| Shear Modulus | 80 GPa | 11600 ksi | 80 GPA | 11600 psi | |

* Estimated. Pennsy estimated the properties attributed to competitive parts. The properties represented were chosen as the best available representation of spring steel. Actual properties likely have less elongation.

Pennsy’s Pedestal Roof Liner Laboratory Test Results

At the Pennsy test center we built a test machine and fixture to simulate the interface and forces subjected to a Pedestal Roof Liner. The vertical testing consists of cycling a vertical force of 20,000 lbs @ 1hz through a side frame fixture onto a bearing adapter. This test ran until failure. The lateral testing consist of 15,000 lbs constant vertical load, with ¼” lateral displacement, fully reversed @ 0.5 hertz for 100,000 cycles.

The results showed the Pennsy part has a greater than 10x better performance when compared to the standard clip-on liners. In vertical testing the competitor’s clip-on liner, made with spring steel, failed in under 108,000 cycles. The heavier Dyna-Clip failed in under 80,000 cycles. The Pennsy part went greater than 1,000,000 cycles without failure!

Lateral testing shows no measurable wear on either the Pennsy or competitor’s clip-on roof liner. However, multiple cracks were observed on the competitor’s clip-on roof liner. The standard liner also caused 1/32″ of wear to the bearing adapter. The Pennsy liner did not crack and caused NO measurable wear to the adapter.

Pennsy’s pedestal roof liner is a superior performing part at a low cost. It will outperform all pedestal roof liners currently available. Pennsy’s pedestal roof liner has elongation that is three times that of its peers with a lower hardness to improve survivability. Failures of our pedestal roof liner will occur as intended, due to wear of the liner, not because of forced FRA mandated replacements owing to cracking and breaking.

Call Pennsy and ask to see the complete test results.